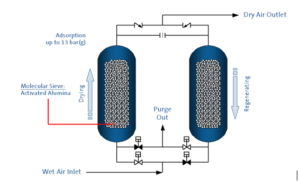

A heatless pressure swing adsorption (PSA) air dryer package is a system that continuously supplies moisture-free compressed air to downstream equipment. This system consists of two identical adsorption vessels, each filled with high-performance molecular sieve desiccant for moisture removal.

The operation of the system is fully automatic and controlled by a PLC, ensuring a stable dew point and minimal pressure drop throughout the process.

The dryer operates in a four-stage cyclic process:

1. Adsorption

Moist compressed air enters the on-line vessel, where water vapor is adsorbed by the molecular sieve desiccant. The resulting dry air exits from the top of the vessel and is delivered to the system at the required dew point.

2. Regeneration

A portion of the dry outlet air from the first vessel is expanded to near atmospheric pressure and passed in reverse flow through the second vessel. This low-pressure dry air removes the accumulated moisture from the desiccant and is discharged to the atmosphere through a silencer.

3. Pressure Equalization (Equalizing)

Before switching the vessels, both towers are temporarily interconnected to equalize the pressure between them. This pressure balancing prevents mechanical stress on the valves and the molecular sieve desiccant during the transition phase.

4. Depressurization

The saturated vessel is depressurized to near atmospheric pressure to facilitate moisture release, after which the regeneration process begins.

The capacity range of dryers designed by Green Mile Company depends on the dryer type and size. The typical operating range for this type of dryer is as follows:

• Capacity range: 20 – 20000 Nm3/hr

• Dew point: -40 ~ -70 °C