Industrial agitators are widely used in most chemical processes to carry out reactions inside vessels. In these processes, two or more miscible or immiscible process fluids may be present. Industrial agitators are employed to perform chemical or physical reactions in liquid phase, gas–liquid phase, liquid–solid phase, and gas–liquid–solid phase systems, in which the liquid phase is considered the continuous phase, while the gas and solid phases are regarded as dispersed phases.

Agitators consist of the following main components:

* Motor

Motors are manufactured with various speeds and power ratings. Commonly used rotational speeds are in the range of 1200–1800 rpm. However, in mixing processes, the mixer speed is reduced by a gearbox in order to increase the motor torque.

* Baffle

Baffles are generally used in turbulent flow conditions, and there is no need for them when mixing viscous fluids under laminar flow. In the absence of baffles, the fluid mass rotates as a solid body inside the vessel, and effective mixing does not occur.

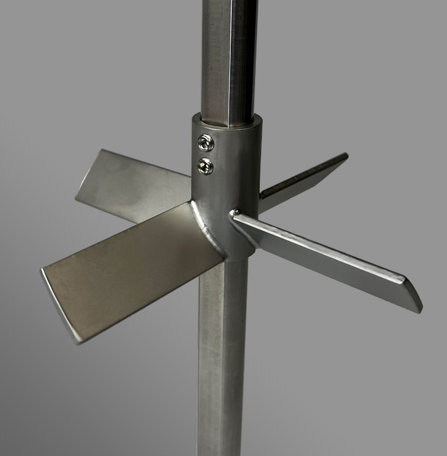

* Impeller

The impeller is the most critical component of an agitator, and all design requirements and operating conditions must be considered when selecting its type. Incorrect impeller selection can lead to improper flow patterns and adversely affect parameters such as motor power consumption and reaction rate.

* Gearbox

Gearboxes reduce the motor speed at constant power, thereby increasing the rotational torque required to drive the impeller.

* Shaft

The shaft is a cylindrical rod that transmits the driving force from the motor to the impeller. In most cases, a solid shaft is used; however, in gas–liquid systems where recirculation of gas from the vessel headspace back into the liquid is required, hollow shafts are also employed.

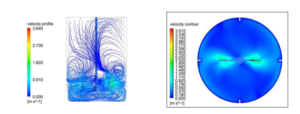

Green Mile Company utilizes numerical simulation software (CFD) such as ANSYS Fluent and SolidWorks Flow Simulation for design purposes, flow simulation, and impeller selection. By considering the effects of fluid regime forces acting on the shaft, the company proposes optimal configurations to achieve stable operating conditions.