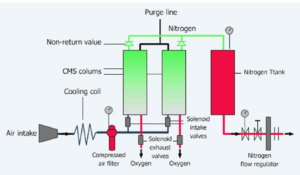

Nitrogen production by the Pressure Swing Adsorption (PSA) method separates nitrogen from air by utilizing the difference in adsorption characteristics of nitrogen and oxygen on a carbon molecular adsorbent, known as Carbon Molecular Sieve (CMS). The PSA system consists of two vessels filled with CMS.

Compressed air containing approximately 78% nitrogen and 21% oxygen enters the first vessel through a nozzle installed at the bottom and flows upward through the Carbon Molecular Sieve (CMS) bed. As the air passes through the adsorbent, due to its highly porous structure with very fine pores, oxygen, carbon dioxide, and water vapor are adsorbed, while nitrogen with the required purity exits the vessel through the top nozzle.

After completion of the adsorption step, the CMS adsorbent becomes saturated with oxygen and the vessel enters the regeneration stage. During this stage, a portion of the produced high-purity nitrogen, known as purge gas, is redirected back into the vessel through the top nozzle to desorb and remove the adsorbed oxygen from the CMS. This process regenerates the adsorbent and prepares the vessel for the next adsorption cycle.

In continuous operation, one tower is always in the adsorption mode while the other is in regeneration mode. This alternating operation ensures a stable and continuous supply of nitrogen to the end user.

The production capacity of the nitrogen generation packages manufactured by this company depends on the applied technology, required purity, and industrial application. The typical operating ranges for these nitrogen generation packages are as follows:

•Capacity range: 1–20,000 Nm³/hr

•Nitrogen purity range: 90%–99.5%